Engine Exhaust Valve

Marine Diesel Exhaust Valve Description:

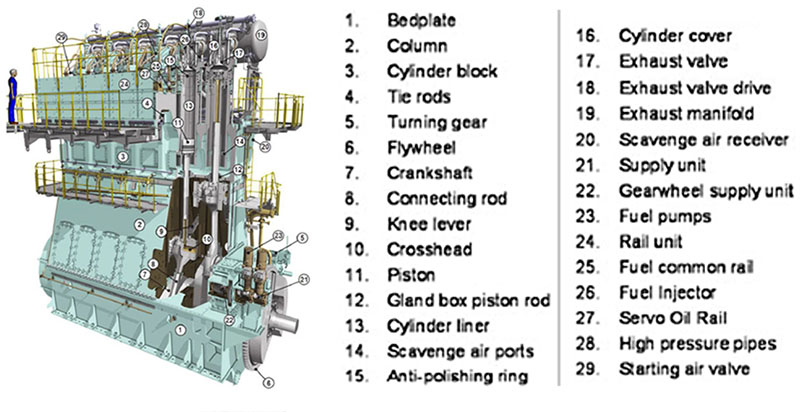

Marine diesel exhaust valve is an important part of the diesel engine. It is installed on the cylinder head, and together with the cylinder head, cylinder liner, and piston constitutes the combustion chamber of the diesel engine. The working performance of the engine exhaust valve affects the stability, reliability, power, economy, and exhaust gas index of the diesel engine.

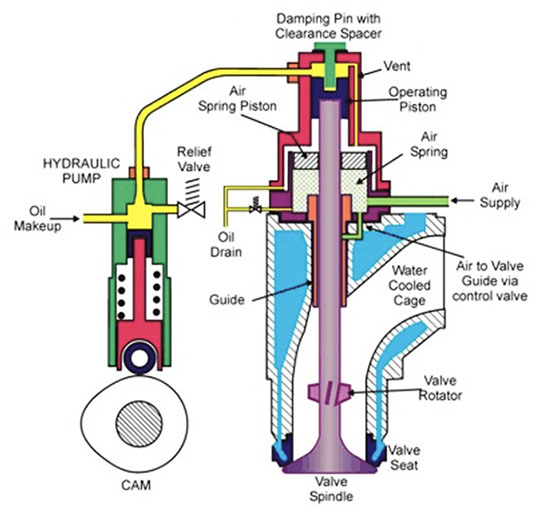

Lubricating oil from the hydraulic pump (from the engine LO system) operates the piston in the exhaust valve, which pushes the valve open. Air at 7 bar is directed through the one-way valve to the underside of the piston connected to the valve stem. As the valve opens, the air under the piston is compressed.

When the hydraulic pressure is released, the expansion of the compressed air helps the valve close. There is a small amount of lubricating oil in the air. Air is also directed to the exhaust valve guides.

This keeps the guide cool and lubricated and prevents exhaust gas from leaking from the guide. Excess oil collects at the bottom of the air spring cylinder and drains into a collection tank.

The exhaust valve spindle is equipped with a valve rotor. The kinetic energy in the exhaust gas causes the valve to rotate a small amount as it passes through. This keeps the valve at an even temperature and helps reduce the build-up of deposits on the valve seat.

Construction of the marine engine exhaust valve:

The main engine exhaust valve of the marine diesel engine consists of

- Exhaust valve housing: The housing made of cast iron contains the different components and drives for the exhaust valve. It also has a jacket through which cooling water is passed to maintain the valve temperature

- Valve and Spindle: When operating in the open and closed positions, the spindle is responsible for pulling exhaust gases out of the engine cylinders. The mandrel can be a molybdenum chrome alloy with a layer of Stellite, welded to the seat face, or a heat resistant Nimonic alloy head, friction welded to an alloy steel shaft. The valve stem is equipped with a winged valve rotator.

- Exhaust valve seat: The exhaust valve seat is a regenerable valve seat that can be repaired or replaced in the event of damage, usually made of hardened molybdenum steel with good temperature resistance. There is a spring air piston chamber with an air supply connection. The hydraulic oil chamber and operating piston are located at the top of the valve spindle.

Operation of Diesel Engine Main Exhaust Valve

The camshaft of the marine diesel exhaust valve is connected to the crankshaft by a chain or gear. Once the cam enters the cam profile, the hydraulic oil pump will overcome the spring force and deliver high-pressure oil to the exhaust valve.

The pressure of hydraulic oil to operate the vent valve can be up to 220 bar.

When the hydraulic oil pushes the working piston connected to the valve stem, the valve will move down, allowing the exhaust gas in the cylinder to flow out of the engine to the exhaust pipe.

The kinetic energy in the exhaust rotates the valve as the wing valve rotator keeps the valve at an even temperature and helps reduce the build-up of deposits on the valve seat.

Once the hydraulic oil pump rollers come out of the cam profile and into the cam ring, the spring pressure will cut off the supply of hydraulic oil.

The air supply under the spring air piston will now close the valve and seal it against the valve seat, preventing exhaust gas from flowing out of the cylinder. The air pressure to close the valve is approximately 7 bar.

When the valve is closed by air pressure, the oil remaining in the hydraulic oil chamber is expelled from the discharge valve.

Damping on top of the exhaust valve piston prevents seat hammering.

In most modern engines, air pressure is used to close the valves. However, in some older engines, a spring is used instead of air pressure to close the valve.

The main engine exhaust valve overhaul interval depends on the manufacturer and type of exhaust valve.

However, in modern marine engines, the interval can reach 36,000 hours; after that, the valves will need an overhaul.

Exhaust valve material

- Valve cage & guide: cast iron

- Valve seat: hardened molybdenum steel

- Valve spindle: molybdenum-chromium alloy, a layer of Stellite is welded on the seat surface.

Marine Exhaust Valve Parts:

Marine Engine Exhaust Valve Brands

marine diesel engine exhaust valve

We offer the Brands and Spear parts:

|

SULZER:

|

||||

| RD68 | RND76 | RND76M | RND90 | RND90M |

| ZL40/48 | RTA62 | RND68M | RTA84 | 16ZAV40S |

| RLA90 | RTA72 | RTA84M | RTA84C | RND68 |

| RTA52 | RTA58 | RTA76 | RLB90 | RTA48(T) |

| RTA38 | RTA76 | RTA96 | RLA(B)56 | RLA(B)66 |

| RLA(B)76 | RF44 | RF56 | TAD36 | TAD48 |

|

MAN:

|

||||

| 40/54A | 52/90N | 57/80C | KZ57/80F | |

| KSZ70/125 | KSZ78/155 | 90/160A | 52/55 | |

| L58/64 | 90/190CL | 60/105E | 70/120E | |

| 70/125CL | KSZ78/155A | KSZ70/125BL | 52/55A, 40/45 | |

|

B&W:

|

||||

| L35MC | L60MC | L80MC | L55GF | L55GFCA |

| L80GFCA | L80GB | 74VT2BF | K62EF | K74EF |

| K84EF | K45GFC | K67GF | K80GF | K90GF |

| S45HU | L70MC | L50MCE | S60MC | S70MCE |

| K80MC | S80MC | K90MC-C | L67GFCA | L90GBE |

| K45GF | L45GF | L67GF | L80GF | L90GF |

| S35MC | L42NC | S42NC | L50MC | S60MC |

| L70MC | L80MC | L90MC | S90MC | 50VT2BF |

| 62VT2BF | K84EF | |||

|

MITSUBISHI:

|

|||

| UEC37L/LA/LS | UEC45HA | UEC60L/LA/LS | |

| UEC45L/LA/LS | UET45/75C | UEC52/125H | |

| UEC52L/LA/LS | UET45/80D | UEC52/90D | |

| UEC(T)52/105D | UEC45/115H | UEC37/88H | UEC37H |

|

PIELSTICK:

|

||||

| PA6 | PC3 | PC2-2 | IHI PC2-5 | PC4 |

| PC2-6 | PC4-2L | PC4-570 | PA5 | |

|

AKASAKA:

|

||||

| UET45/80D | UEC52/105D | DM51SS | UEC 60/150H | UEC 60HA |

| A31 | A34 | A37 | A41 | AH27 |

| AH28 | AH30 | AH36 | AH38 | AH40 |

| DM30 | DM36 | DM38 | DM46 | DM47 |

|

DEUTZ:

|

||||

| RBV8M358 | RBV8M540 | RBV16M640 | TBD620L6 | |

| BVM350 | BVM540 | BF6M716 | ||

|

HANSHIN:

|

||||

| EL30 | EL32 | EL35 | EL40 | EL44 |

| LH28RG | LH31G | LU28(A,R,G) | LU32 | LU35 |

| LU38 | LU46(A) | LU50 | LU54 | LUN28 |

| LUN30 | LUD32 | LUD35 | LUS38 | |

|

NIIGATA:

|

|||

| MG40X(EX) | M34X | 6M28BFT | M31X |

|

MAK:

|

||||

| M332 | M453AK | MU551AK | MU552AK | M601 |

| MU452AK | 451AK | 6M453AK | 9M453C | 6M601C |

| 8M601 | ||||

|

WARTSILA:

|

||||

| 22 | 32 | 31 | 26 | 20 |

| S28 | 38 | 46 | 32GD | 46GD |

| 14TK | R22HF | R-V32 | NOHAB | |

|

DAIHATSU:

|

||||

| PS-18 | PS-22 | PS-20 | PS-26 | PS-30 |

| PKT-14 | PKT-16 | PKTD-16 | DS-18 | DS-22 |

| DS-26 | DS- 28 | DS-32 | DL-14 | DL-16 |

| DL-19 | DL-20 | DL-22 | DL-24 | DL-26 |

| DK-20 | PL-24 | |||

|

CUMMINS:

|

||||

| 4BT3.9 | 6BT(A)5.9 | 6CT8.3 | NT(A)855 | N14 |

| KTA19 | KTA38 | KTA50 | QSK19 | QSM11 |

|

CATERPILLAR:

|

||||

| 3054 | 3056 | 3066 | 3106 | 3126 |

| 3306 | 3406 | 3408 | 3412 | 3508 |

| 3512 | 3516 | 3606 | 3608 | 3612 |

| 3616 | 3618 | C1.5 | C2.2 | C7 |

| C9 | C10 | C12 | C15 | C16 |

| C18 | C30 | C32 | ||

|

SCANIA:

|

||||

| DI 09 | DI 13 | DI 16 | ||

- Marine Engine Connecting Rods: The Ultimate Guide

- Marine Gate Valves

- Exploring Marine Diesel Engine Connecting Rods: Anatomy, Materials, Design and Maintenance

- 4 important rudder maintenance instructions

- Marine Propeller Shafts: Consider Selecting the Right One

- The Importance of Marine Engine Connecting Rods in Performance Engines