Marine Diesel Stuffing Box

Marine Diesel Stuffing Box

Main Engine Stuffing Box is a sealing gland that has many applications on a ship. It is a kind of packing material used to seal pumps, valves, stern tubes, etc. It is also used in boats, where the propeller shaft protrudes out of the hull. When water and other liquids seep into a boat’s propeller or engine, the results can be catastrophic, which is why a stuffing box is needed.

Stuffing box serves two main purposes:

- It acts as a sealing material to prevent leaks

- It keeps the system operational and in cool condition.

Marine Diesel Stuffing Box Arrangement

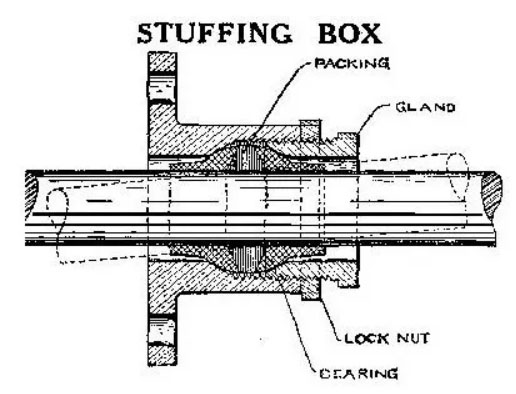

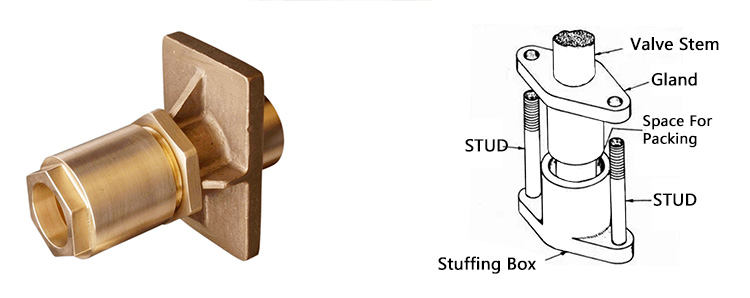

In most of the pumps, and even in the ship’s propeller shaft, the stuffing box consists of a stack of packing rings or a short square cross-sectional rope made of greased flax. The material is closely packed or wound tightly around the propeller or pump shaft with a threaded nut or spacer compressing it in place. There are also hose clamps attached to the stuffing box, which are then attached to a short piece of heavy-duty rubber hose. The rubber hose is clamped around the place where the propeller opens in the ship’s hull.

A stuffing box is also seen in steam engines, at the place where the piston rod reciprocates with the cylinder cover, which helps in preventing leakage of steam from the cylinder.

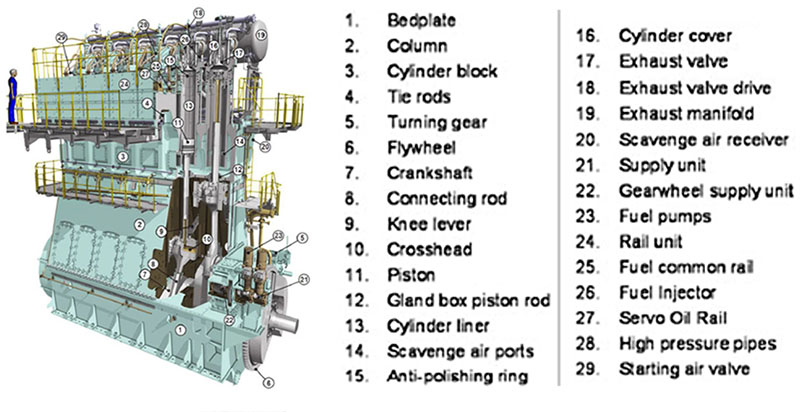

In diesel engines, a stuffing box is found in the bore for the piston rod at the bottom of the scavenge air box. The stuffing box prevents the entry of lubricating oil from the crankcase into the scavenge air space. It also prevents the leaking of air from scavenging space to the crankcase.

Construction of Diesel Engine Stuffing Box

The whole arrangement is distributed into two parts, put together by a flanged joint. The housing generally consists of five ring grooves of which the two uppermost grooves accommodate sealing rings to prevent blowing down of scavenging air along the piston rod. The bottom groves are fitted with scrapper rings in order to scrap the lubricating oil on the piston rod. The oil enters and leaves the housing through bores. The two sealing rings are generally made of brass while the scrapper rings are made of steel.

In between the two types of rings, a cofferdam attached with connecting pipes and bores is provided, which communicates with a control clock fitted on the engine. It is used to monitor the performance of sealing and scrapper rings

Special Features

It specifically fits all the Marine Diesel Stuffing Boxs packed with flax rings to allow a bit of leakage. The sealing is adjusted to receive a few drops of fluid per minute to maintain lubrication and subside the heat generated due to the continuous motion of the shaft. This amount of water is not considered leakage and seldom creates a problem. Few other types of sealing arrangements, such as mechanical face seals and lip seals, use materials or lubrication systems that are more technically advanced. There are also drip-fewer seals made of Teflon or carbon.

Piston Material

- Housing: Cast Iron or Cast Steel

- Rings: bronze or steel or PTTF being introduced newly

- Lamellas: cast iron or carbon

Stuffing Box Spares:

Marine Diesel Stuffing Box Brands

We offer the Brands and Spear parts:

|

SULZER:

|

||||

| RD68 | RND76 | RND76M | RND90 | RND90M |

| ZL40/48 | RTA62 | RND68M | RTA84 | 16ZAV40S |

| RLA90 | RTA72 | RTA84M | RTA84C | RND68 |

| RTA52 | RTA58 | RTA76 | RLB90 | RTA48(T) |

| RTA38 | RTA76 | RTA96 | RLA(B)56 | RLA(B)66 |

| RLA(B)76 | RF44 | RF56 | TAD36 | TAD48 |

|

MAN:

|

||||

| 40/54A | 52/90N | 57/80C | KZ57/80F | |

| KSZ70/125 | KSZ78/155 | 90/160A | 52/55 | |

| L58/64 | 90/190CL | 60/105E | 70/120E | |

| 70/125CL | KSZ78/155A | KSZ70/125BL | 52/55A, 40/45 | |

|

B&W:

|

||||

| L35MC | L60MC | L80MC | L55GF | L55GFCA |

| L80GFCA | L80GB | 74VT2BF | K62EF | K74EF |

| K84EF | K45GFC | K67GF | K80GF | K90GF |

| S45HU | L70MC | L50MCE | S60MC | S70MCE |

| K80MC | S80MC | K90MC-C | L67GFCA | L90GBE |

| K45GF | L45GF | L67GF | L80GF | L90GF |

| S35MC | L42NC | S42NC | L50MC | S60MC |

| L70MC | L80MC | L90MC | S90MC | 50VT2BF |

| 62VT2BF | K84EF | |||

|

MITSUBISHI:

|

|||

| UEC37L/LA/LS | UEC45HA | UEC60L/LA/LS | |

| UEC45L/LA/LS | UET45/75C | UEC52/125H | |

| UEC52L/LA/LS | UET45/80D | UEC52/90D | |

| UEC(T)52/105D | UEC45/115H | UEC37/88H | UEC37H |

|

PIELSTICK:

|

||||

| PA6 | PC3 | PC2-2 | IHI PC2-5 | PC4 |

| PC2-6 | PC4-2L | PC4-570 | PA5 | |

|

AKASAKA:

|

||||

| UET45/80D | UEC52/105D | DM51SS | UEC 60/150H | UEC 60HA |

| A31 | A34 | A37 | A41 | AH27 |

| AH28 | AH30 | AH36 | AH38 | AH40 |

| DM30 | DM36 | DM38 | DM46 | DM47 |

|

DEUTZ:

|

||||

| RBV8M358 | RBV8M540 | RBV16M640 | TBD620L6 | |

| BVM350 | BVM540 | BF6M716 | ||

|

HANSHIN:

|

||||

| EL30 | EL32 | EL35 | EL40 | EL44 |

| LH28RG | LH31G | LU28(A,R,G) | LU32 | LU35 |

| LU38 | LU46(A) | LU50 | LU54 | LUN28 |

| LUN30 | LUD32 | LUD35 | LUS38 | |

|

NIIGATA:

|

|||

| MG40X(EX) | M34X | 6M28BFT | M31X |

|

MAK:

|

||||

| M332 | M453AK | MU551AK | MU552AK | M601 |

| MU452AK | 451AK | 6M453AK | 9M453C | 6M601C |

| 8M601 | ||||

|

WARTSILA:

|

||||

| 22 | 32 | 31 | 26 | 20 |

| S28 | 38 | 46 | 32GD | 46GD |

| 14TK | R22HF | R-V32 | NOHAB | |

DAIHATSU: |

||||

| PS-18 | PS-22 | PS-20 | PS-26 | PS-30 |

| PKT-14 | PKT-16 | PKTD-16 | DS-18 | DS-22 |

| DS-26 | DS- 28 | DS-32 | DL-14 | DL-16 |

| DL-19 | DL-20 | DL-22 | DL-24 | DL-26 |

| DK-20 | PL-24 | |||

|

CUMMINS:

|

||||

| 4BT3.9 | 6BT(A)5.9 | 6CT8.3 | NT(A)855 | N14 |

| KTA19 | KTA38 | KTA50 | QSK19 | QSM11 |

|

CATERPILLAR:

|

||||

| 3054 | 3056 | 3066 | 3106 | 3126 |

| 3306 | 3406 | 3408 | 3412 | 3508 |

| 3512 | 3516 | 3606 | 3608 | 3612 |

| 3616 | 3618 | C1.5 | C2.2 | C7 |

| C9 | C10 | C12 | C15 | C16 |

| C18 | C30 | C32 | ||

|

SCANIA:

|

||||

| DI 09 | DI 13 | DI 16 | ||