3 types of Oil System in a ship

Lubricating Oil System

Engine lubrication system is important for a Marine Main Engine, as an Engine consists of various rotating and moving parts, so we need to lubricate it well otherwise they wear and tear out, and we may face Engine breakdown.

Main Bearing Oil System

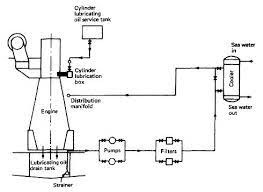

This system supplies lubricating oil to the engine bearings and cooling oil to the pistons. Lubricating oil is pumped from ME LO Circulating Tank, placed in the double bottom beneath the engine, by means of the ME LO Pump, to the ME LO Cooler, a thermostatic valve, and through a full-flow filter, to the engine, where it is distributed to the various branch pipes. Pumps and fine filters are arranged in duplicate, with one as a standby. From the engine, the oil collects in the oil pan, from where it is drained to the ME LO Circulating Tank for reuse. A centrifuge is arranged for cleaning the lubricating oil in the system and the clean oil can be provided from a storage tank.

Crosshead Bearing Oil System

The operating pressure of the crosshead bearing oil is 10-12kg/cm2, and the supply to the crosshead is via a toggle lever pipe arrangement. High-pressure crosshead bearing oil is also used to lubricate the connecting rod bottom end bearings, supply to these being via holes drilled in the connecting rods. The high-pressure crosshead system also supplies oil for the engine reversing servomotors and as make-up for the exhaust valve actuator system. For actuating the exhaust valves, the oil pressure is raised by the actuator pumps to about 160kg/cm2.