Marine Engine Fuel Pump

Marine Engine Fuel Pump:

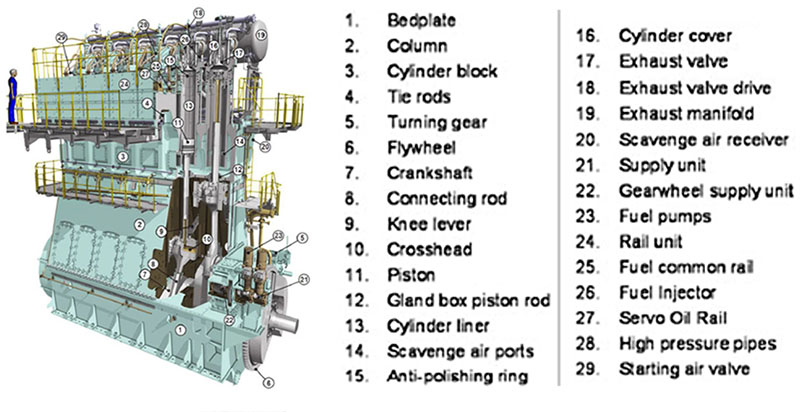

A Marine Engine Fuel Pump is a part of a ship that supplies fuel from a fuel container to the carburetor of an internal combustion engine. The main fuel pump controls the amount and timing of fuel injected into the combustion space and provides the high fuel pressure required to hydraulically operate the fuel injection. Late or early injection can result in insufficient power and engine damage.

Fuel injection is done with the help of cams and camshafts. The cams mounted on the camshaft operate the fuel pump driven by the crankshaft, one for each cylinder. The speed of the camshaft is the same as the engine speed of a 2-stroke engine, while the speed of a 4-stroke engine is half the engine speed.

Basic Working principle of fuel pump

As the cam rotates, it operates a spring-loaded plunger (plunger) that moves up and down in a cylinder (barrel). As the plunger moves up, the fuel pressure in the barrel above the plunger rises rapidly. The high-pressure fuel then opens the fuel valve (injector) and sprays it into the cylinder in tiny droplets called atomization. It is important to note that injection only occurs when the plunger moves up the cam ramp.

2 Types of Fuel Pump

-

Port-Controlled Helix Jerk Pump

This is a common fuel pump, widely used in MAN B&W engines as well as 4-stroke engines.

The fuel pump includes a cam-operated single-acting plunger with a fixed stroke. A helix is machined into the plunger, and the helix also forms a vertical groove and an annular groove at the bottom of the helix. The plunger reciprocates inside the barrel, the pump body has overflow ports that connect to the suction side of the pump, and when the cams are on the base circle, they drill holes above the top of the plunger. The plunger is keyed to the sleeve, and a gear (pinion) is machined in the sleeve. The pinion meshes with a rack that rotates the plunger relative to the barrel. The frame is connected to the engine governor.

During the down stroke, the pump barrel is filled with oil through the suction port. During the upward stroke, the plunger covers the suction and overflow ports. The onset of injection is constant, achieved by the fuel pressure rising above the spring-loaded delivery valve preset pressure. The delivery ends when the edge of the spiral emerges from the overflow. The start of injection is initially set and constant. It starts when the top edge of the plunger covers the suction port and the pressure is greater than the delivery valve setting. The end of the spray is variable and controlled by the spiral edge that exposes the spill. (This can be changed by moving the rack and pinion mechanism that rotates the plunger and screw). The oil spill port spills fuel back to the suction side.

-

Suction and Spill Controlled Fuel Pump

A common plunger reciprocates in the barrel. As the plunger moves up and down, two pivot levers operate the push rod, opening the suction and relief valves. When the cam follower is on the base circle of the cam, the suction valve opens and the overflow valve closes. When the plunger moves up the barrel, the suction push rod moves down and the suction valve closes. Injection then begins, and fuel is delivered to the injector through the one-way valve. As the plunger continues upward, the overflow plunger will open the overflow valve, the pressure above the plunger will drop, and the injection will stop.

Main Engine Fuel Pump Spares:

Marine Engine Fuel Pump Spares:

We offer the Brands and Spear parts:

|

SULZER:

|

||||

| RD68 | RND76 | RND76M | RND90 | RND90M |

| ZL40/48 | RTA62 | RND68M | RTA84 | 16ZAV40S |

| RLA90 | RTA72 | RTA84M | RTA84C | RND68 |

| RTA52 | RTA58 | RTA76 | RLB90 | RTA48(T) |

| RTA38 | RTA76 | RTA96 | RLA(B)56 | RLA(B)66 |

| RLA(B)76 | RF44 | RF56 | TAD36 | TAD48 |

|

MAN:

|

||||

| 40/54A | 52/90N | 57/80C | KZ57/80F | |

| KSZ70/125 | KSZ78/155 | 90/160A | 52/55 | |

| L58/64 | 90/190CL | 60/105E | 70/120E | |

| 70/125CL | KSZ78/155A | KSZ70/125BL | 52/55A, 40/45 | |

|

B&W:

|

||||

| L35MC | L60MC | L80MC | L55GF | L55GFCA |

| L80GFCA | L80GB | 74VT2BF | K62EF | K74EF |

| K84EF | K45GFC | K67GF | K80GF | K90GF |

| S45HU | L70MC | L50MCE | S60MC | S70MCE |

| K80MC | S80MC | K90MC-C | L67GFCA | L90GBE |

| K45GF | L45GF | L67GF | L80GF | L90GF |

| S35MC | L42NC | S42NC | L50MC | S60MC |

| L70MC | L80MC | L90MC | S90MC | 50VT2BF |

| 62VT2BF | K84EF | |||

|

MITSUBISHI:

|

|||

| UEC37L/LA/LS | UEC45HA | UEC60L/LA/LS | |

| UEC45L/LA/LS | UET45/75C | UEC52/125H | |

| UEC52L/LA/LS | UET45/80D | UEC52/90D | |

| UEC(T)52/105D | UEC45/115H | UEC37/88H | UEC37H |

|

PIELSTICK:

|

||||

| PA6 | PC3 | PC2-2 | IHI PC2-5 | PC4 |

| PC2-6 | PC4-2L | PC4-570 | PA5 | |

|

AKASAKA:

|

||||

| UET45/80D | UEC52/105D | DM51SS | UEC 60/150H | UEC 60HA |

| A31 | A34 | A37 | A41 | AH27 |

| AH28 | AH30 | AH36 | AH38 | AH40 |

| DM30 | DM36 | DM38 | DM46 | DM47 |

|

DEUTZ:

|

||||

| RBV8M358 | RBV8M540 | RBV16M640 | TBD620L6 | |

| BVM350 | BVM540 | BF6M716 | ||

|

HANSHIN:

|

||||

| EL30 | EL32 | EL35 | EL40 | EL44 |

| LH28RG | LH31G | LU28(A,R,G) | LU32 | LU35 |

| LU38 | LU46(A) | LU50 | LU54 | LUN28 |

| LUN30 | LUD32 | LUD35 | LUS38 | |

|

NIIGATA:

|

|||

| MG40X(EX) | M34X | 6M28BFT | M31X |

|

MAK:

|

||||

| M332 | M453AK | MU551AK | MU552AK | M601 |

| MU452AK | 451AK | 6M453AK | 9M453C | 6M601C |

| 8M601 | ||||

|

WARTSILA:

|

||||

| 22 | 32 | 31 | 26 | 20 |

| S28 | 38 | 46 | 32GD | 46GD |

| 14TK | R22HF | R-V32 | NOHAB | |

|

DAIHATSU:</div >

|

||||

| PS-18 | PS-22 | PS-20 | PS-26 | PS-30 |

| PKT-14 | PKT-16 | PKTD-16 | DS-18 | DS-22 |

| DS-26 | DS- 28 | DS-32 | DL-14 | DL-16 |

| DL-19 | DL-20 | DL-22 | DL-24 | DL-26 |

| DK-20 | PL-24 | |||

|

CUMMINS:

|

||||

| 4BT3.9 | 6BT(A)5.9 | 6CT8.3 | NT(A)855 | N14 |

| KTA19 | KTA38 | KTA50 | QSK19 | QSM11 |

|

CATERPILLAR:

|

||||

| 3054 | 3056 | 3066 | 3106 | 3126 |

| 3306 | 3406 | 3408 | 3412 | 3508 |

| 3512 | 3516 | 3606 | 3608 | 3612 |

| 3616 | 3618 | C1.5 | C2.2 | C7 |

| C9 | C10 | C12 | C15 | C16 |

| C18 | C30 | C32 | ||

|

SCANIA:

|

||||

| DI 09 | DI 13 | DI 16 | ||

- Marine Cylinder Liner Standards: A Technical Overview

- How Marine Engine Connecting Rods Affect Your Engine Performance

- 5 Indications of Urgent Diesel Crankshaft Repair

- Oil Lubrication Stern Shaft Seal

- Construction Explanation: What is a Marine Engine Bedplate?

- Quality Cylinder liner: Sulzer RTA72, RTA72UB RTA52 RTA58 RND68