High-performance Diesel Engine Crankshaft

Marine Diesel Engine Crankshaft:

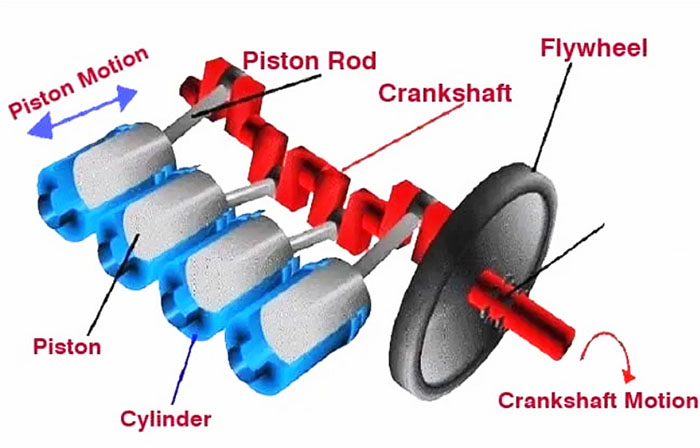

The Crankshaft of a marine engine is a mechanical device that converts the reciprocating motion of the engine piston into rotational motion. The crankshaft of the engine is connected to the piston through a connecting rod. The main purpose of this connecting rod is to receive the reciprocating motion of the engine pistons and transmit it to the diesel engine crankshaft.

Different engines complete a power cycle at different crankshaft revolutions. For example, a 2-stroke engine completes one power cycle after one crankshaft revolution, while a 4-stroke engine completes one power cycle after two crankshaft revolutions.

How crankshaft works

The diesel crankshaft acts on the crank mechanism. The crank has a crankpin, and a crank connected to the connecting rod. It has a shock absorber that reduces the thrust on the crank.

The crankshaft has a counterweight to reduce bending loads on the crankshaft. The crankshaft of a four-stroke engine works in the following way:

- When the engine piston moves from TDC to BDC (downstroke), it transmits its motion to the crankshaft through the connecting rod.

- The crank further converts the linear motion of the piston into rotational motion and transmits it to the camshaft.

- When the camshaft receives rotational motion, it opens the intake valve and the air-fuel mixture enters the combustion chamber.

- As it fills the combustion chamber with the air-fuel mixture, the piston moves up (from BDC to TDC) and compresses the mixture. During this process, the camshaft closes both the intake and exhaust valves. As the compression process is complete, so is the first rotation of the crankshaft.

- At the end of the compression process, the ignition process occurs.

- The heat released by the compressed mixture due to the ignition process forces the piston to move downward. We call this type of stroke a power stroke. As this piston goes down, the piston again transmits its reciprocating motion to the connecting rod, which in turn transmits it to the crankshaft.

- One end of the crank is connected to the flywheel. When the crank receives the movement of the piston, it transmits this movement to the flywheel. The flywheel stores this movement and further drives the wheels of the vehicle.

- After the power stroke, the engine piston moves further down to expel the exhaust gas. During this process, the camshaft receives the movement of the piston through the crank and opens the exhaust valve, while the intake valve remains closed. The piston pushes the exhaust gas out of the combustion chamber.

- At the end of the exhaust stroke, the crank makes two revolutions, and the four-stroke engine also completes a power cycle. After this, the entire cycle repeats.

4 Types of Engine Crankshafts

There are 4 major types of crankshafts:

- Fully manufactured Crankshafts(cast or forged)

- Semi-built Crankshaft

- Welded Crankshaft

- Flanged Coupling Crankshaft

Construction of Crankshaft Material

The following are the materials used to make the crankshaft:

- Cast Iron

- Carbon Steel

- Vanadium Microalloyed Steel

- Forged Steel

The crank is assembled from different parts or made in one piece (monolithic).

The monolithic type cranks are the most popular in the world. However, some internal combustion engines large and small already have crankshafts assembled.

These shafts can also be cast in malleable iron, modular steel or ductile iron. I cast welded parts from steel. This cost-friendly method is used for inexpensive production engines with reasonable loads. The forging process has excellent strength. Therefore, the forging process is known as the preferred process for crankshaft manufacturing.

Components of Crankshaft

We supply the main engine crankshaft parts below:

- Main Journal

- Crankshaft Pulley

- Oil Passway

- Balance Hole

- Counterweight

- Crankshaft Lubrication

Engine Crankshaft Parts:

Marine Engine Crankshaft Brands

We offer the Brands and Spear parts:

|

SULZER:

|

||||

| RD68 | RND76 | RND76M | RND90 | RND90M |

| ZL40/48 | RTA62 | RND68M | RTA84 | 16ZAV40S |

| RLA90 | RTA72 | RTA84M | RTA84C | RND68 |

| RTA52 | RTA58 | RTA76 | RLB90 | RTA48(T) |

| RTA38 | RTA76 | RTA96 | RLA(B)56 | RLA(B)66 |

| RLA(B)76 | RF44 | RF56 | TAD36 | TAD48 |

|

MAN:

|

||||

| 40/54A | 52/90N | 57/80C | KZ57/80F | |

| KSZ70/125 | KSZ78/155 | 90/160A | 52/55 | |

| L58/64 | 90/190CL | 60/105E | 70/120E | |

| 70/125CL | KSZ78/155A | KSZ70/125BL | 52/55A, 40/45 | |

|

B&W:

|

||||

| L35MC | L60MC | L80MC | L55GF | L55GFCA |

| L80GFCA | L80GB | 74VT2BF | K62EF | K74EF |

| K84EF | K45GFC | K67GF | K80GF | K90GF |

| S45HU | L70MC | L50MCE | S60MC | S70MCE |

| K80MC | S80MC | K90MC-C | L67GFCA | L90GBE |

| K45GF | L45GF | L67GF | L80GF | L90GF |

| S35MC | L42NC | S42NC | L50MC | S60MC |

| L70MC | L80MC | L90MC | S90MC | 50VT2BF |

| 62VT2BF | K84EF | |||

|

MITSUBISHI:

|

|||

| UEC37L/LA/LS | UEC45HA | UEC60L/LA/LS | |

| UEC45L/LA/LS | UET45/75C | UEC52/125H | |

| UEC52L/LA/LS | UET45/80D | UEC52/90D | |

| UEC(T)52/105D | UEC45/115H | UEC37/88H | UEC37H |

|

PIELSTICK:

|

||||

| PA6 | PC3 | PC2-2 | IHI PC2-5 | PC4 |

| PC2-6 | PC4-2L | PC4-570 | PA5 | |

|

AKASAKA:

|

||||

| UET45/80D | UEC52/105D | DM51SS | UEC 60/150H | UEC 60HA |

| A31 | A34 | A37 | A41 | AH27 |

| AH28 | AH30 | AH36 | AH38 | AH40 |

| DM30 | DM36 | DM38 | DM46 | DM47 |

|

DEUTZ:

|

||||

| RBV8M358 | RBV8M540 | RBV16M640 | TBD620L6 | |

| BVM350 | BVM540 | BF6M716 | ||

|

HANSHIN:

|

||||

| EL30 | EL32 | EL35 | EL40 | EL44 |

| LH28RG | LH31G | LU28(A,R,G) | LU32 | LU35 |

| LU38 | LU46(A) | LU50 | LU54 | LUN28 |

| LUN30 | LUD32 | LUD35 | LUS38 | |

|

NIIGATA:

|

|||

| MG40X(EX) | M34X | 6M28BFT | M31X |

|

MAK:

|

||||

| M332 | M453AK | MU551AK | MU552AK | M601 |

| MU452AK | 451AK | 6M453AK | 9M453C | 6M601C |

| 8M601 | ||||

|

WARTSILA:

|

||||

| 22 | 32 | 31 | 26 | 20 |

| S28 | 38 | 46 | 32GD | 46GD |

| 14TK | R22HF | R-V32 | NOHAB | |

|

DAIHATSU:</div >

|

||||

| PS-18 | PS-22 | PS-20 | PS-26 | PS-30 |

| PKT-14 | PKT-16 | PKTD-16 | DS-18 | DS-22 |

| DS-26 | DS- 28 | DS-32 | DL-14 | DL-16 |

| DL-19 | DL-20 | DL-22 | DL-24 | DL-26 |

| DK-20 | PL-24 | |||

|

CUMMINS:

|

||||

| 4BT3.9 | 6BT(A)5.9 | 6CT8.3 | NT(A)855 | N14 |

| KTA19 | KTA38 | KTA50 | QSK19 | QSM11 |

|

CATERPILLAR:

|

||||

| 3054 | 3056 | 3066 | 3106 | 3126 |

| 3306 | 3406 | 3408 | 3412 | 3508 |

| 3512 | 3516 | 3606 | 3608 | 3612 |

| 3616 | 3618 | C1.5 | C2.2 | C7 |

| C9 | C10 | C12 | C15 | C16 |

| C18 | C30 | C32 | ||

|

SCANIA:

|

||||

| DI 09 | DI 13 | DI 16 | ||