Oil Lubrication Stern Shaft Seal

Oil Lubrication Stern Shaft Seal

Marine Oil-lubricated seals are used most often for sealing rotary shaft applications. Oil-lubricated systems are the most common, but ship owners occasionally use water-lubricated and grease-lubricated systems.

Oil-lubricated seals are used most often for sealing rotary shaft applications. Oil-lubricated systems are the most common, but ship owners occasionally use water-lubricated and grease-lubricated systems.

How Oil Lubrication Stern Shaft Seal Work

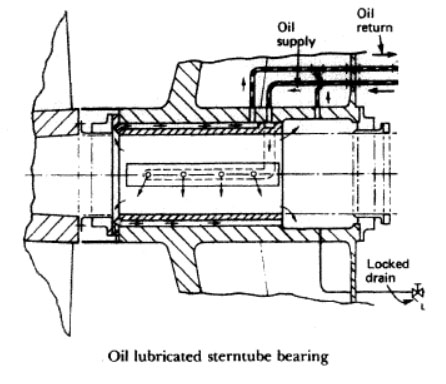

The oil-lubricated Supreme seals close the gap between stationary and moving components of rotating shafts. It prevents the escape of lubricants (oil leakage) and the ingress of harmful materials such as dirt or sand. The lube oil system circulates the oil and controls pressure, flow and temperature in order to build up an appropriate lubrication film for the white metal slide bearing.

ABOUT OUR SEALS

We believe that Oil Lubrication Stern Shaft Seal should provide the best performance to keep you going and give you peace of mind.

Our oil-lubricated shaft seals are used in tailpipes, thrusters, bulkheads, stabilizers, rudder stocks and gearboxes. Oil seals are produced with high-quality housing parts, rubber lip seals, and gaskets.

Technical parameters:

Diameter range of stern shaft:Ø50-Ø1150mm

Outer diameter of stern shaft wear-resisting bush:Ø70-Ø1250mm

Lubricating oil working pressure: 1-2bar

Lubricating oil working temperature: -25℃-+110℃

Stern shaft wear-resisting bush liner velocity:≤7m/sec

Average leakage: 5-30ml/h

Seal Oil System From ScienceDirect:

The sealed oil system prevents gas leakage from the compressor casing. Figure 8.46 is a schematic diagram of a typical seal oil system used in combination with a buffer gas system. These systems require auxiliary equipment such as pumps, regulators, filters, etc. to function properly.… See more on ScienceDirect.