Marine Gate Valves

Marine Gate Valves

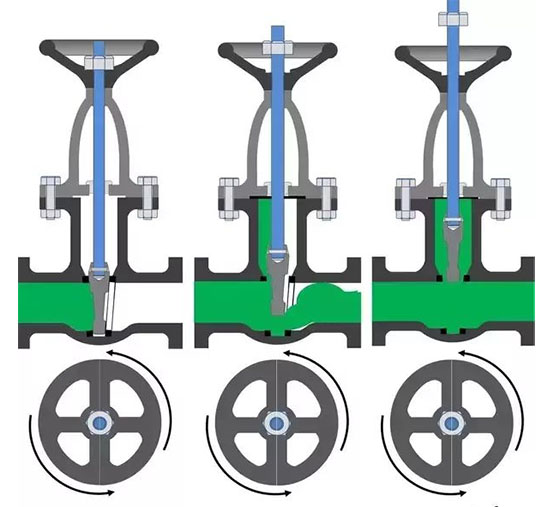

Marine Gate valves are perhaps the first valve you think of in marine plumbing systems. They are used broadly throughout a ship. Marine Gate valves are prized for their simplicity of form and effectiveness of function. Marine Gate valves get their name from the wedge that lifts up and down inside the body of the valve to allow water or other media to pass, much like the gate in a castle. Gate valves are very good in on/off applications, but should not be used in throttling situations to partially limit the amount of flow because the wedge is not designed to handle that kind of horizontal stress without the valve’s seat to support it.

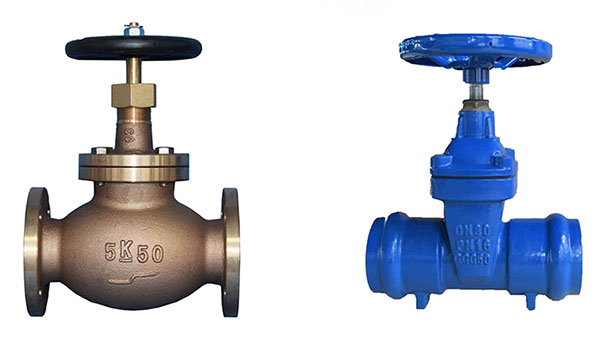

Marine Gate valves material is cast iron, cast steel and cast copper. It is suitable for occasions requiring low flow resistance and low medium pressure, as well as large-diameter pipelines such as seawater, fresh water, fuel oil, and lubricating oil.

Marine Gate Valve Product Range

- Design: JIS, DIN, API, GB

- End Connection: BW, RF, RTJ, UNION

- Size: 1-1/2”~48”, DN40~DN1200, 40A~1200A

- Pressure: JIS 1K~30K, 125LB~2500LB, PN10~PN420

- Material: Cast Iron, Stainless Steel, Bronze

- Operator: H.W., Gear, Pneumatic Actuator, Electric Actuator

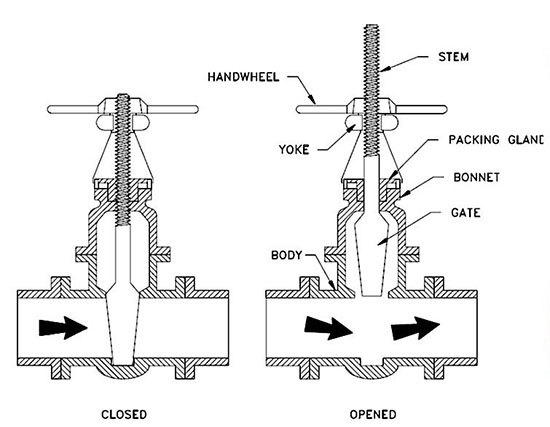

Structure of Marine Gate Valves

The marine gate valve refers to a valve in which the shutter closing member moves in the vertical direction of the center-line of the passage. It is normally composed of the valve body, valve seat, valve stem, gate plate, bonnet, and sealing ring. It can be transformed into a variety of electric gate valves and pneumatic gate valves through the installation of transmission devices and gate valves. It is used for full-open and full-close cut-offs, and cannot be used for regulation and throttling.

Features of Marine Gate Valves

The design takes that the gate valve’s surface is coated fully with top-quality rubber, so it has the characteristics of high flexibility, long service life, zero leakage, etc.

The non-groove is designed at the bottom of the valve body, so it has small local resistance, which also can prevent the water leakage of the valve or damage caused by dirt accumulation.

The cavity of the valve body is treated by spraying; there will not be corrosion and incrustation after being used for a long time, which can effectively prevent secondary pollution, so it is environmental protection and pollution-free production in the twenty-first century.

It does not need to unload the valve from a pipe in use, which can achieve quick maintenance online.

It is easy to install. It is suitable for constrained space, which is also widely used for foodstuff, medicine, plumbing work, architecture and fire fighting, etc, as well as is valued by users.

Main Advantages of Marine Gate Valves

- Marine Gate Valves Have Low Fluid Resistance

The marine gate valve’s body is a straight-through shape that does not alter the flow direction, allowing fluid to pass through the valve (when in the fully open position) with minimal resistance compared to other types of valves.

- Marine Gate Valves Provide Superior Sealing Performance

Marine gate valves provide better sealing performance than shut-off valves. The gate valve’s opening and closing mechanisms are faster and more convenient than those of the shut-off valve.

- Marine Gate Valves Have a Wide Application Range

Marine gate valves are extremely versatile and can be used in applications with mediums like steam, oil, and other media. Plus, gate valves can be used in mediums containing granular solids and with high viscosity. It can also be used as a venting valve and a low vacuum system valve.

- Marine Gate Valves are Bidirectional

Marine gate valves have dual flow directions. They’re not limited to one-way flow, nor are they subject to the flow directions of the medium. Therefore, gate valves are suitable for use in pipelines where the flow direction may change. Plus, they are easier to install than other more sophisticated types of valves.