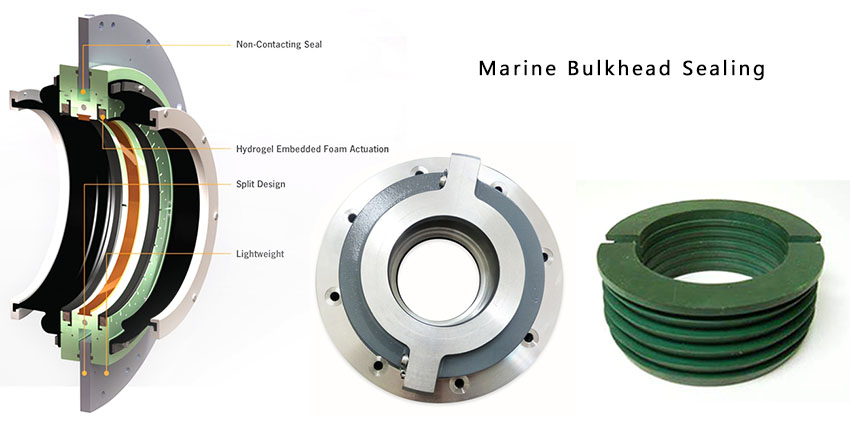

Marine Bulkhead Sealing

Marine Bulkhead Sealing

The Marine Bulkhead Sealing comprises an outer cast aluminum housing and an inner seal manufactured from Novasteen (cloth reinforced phenolic resin).

In normal operation, the inner rotates with the shaft and has running clearance in the housing.

In the event of a compartment on either side of the seal flooding, the water pressure pushes the inner seal axially until it forms a face seal with the outer housing, effectively sealing the compartment.

The design allows for both axial and radial movement.

Bulkhead Sealing pictures:

General Information:

The Marine Bulkhead Sealing can be mounted directly to the bulkhead, however, to enable the change required to satisfy the following specification we recommend the arrangement shown in drawing “BS-200-03”.

- The mounting surface must be flat within 0.15mm

- The mounting surface must be perpendicular to the shaft by 0.2mm

- The mounting surface must be concentric to the shaft within 1mm

Bulkhead Sealing Installation:

- Cut and join the O-ring cord on the shaft using the supplied O-ring glue

- Apply a light coating of grease to the shaft and position the O-ring in the approximate position of the seal.

- Fit the inner seal over the shaft and O-ring, then assemble with the supplied cap crews

- Torque cap screws to 7 foot-pounds.

- Note that the inner has two 3/16” dowels that locate the two halves

- Ensure the seal can move axially

- Assemble the housing over the seal using the supplied cap screws.

Please note the locating dowels are tapered

(Larger on the cap screw side)

- Bolt the seal housing to the mating flange and position the inner seal central in the housing.

Bulkhead Sealing Maintenance:

- The seals are maintenance-free however; the seal faces should be inspected for wear after the first 500 hours and then every 20,000 hours.

- Signs of wear will indicate any alignment problems with the installation.

KEYWORDS: Circumferential Seal; Bulkhead Seal; Lip Seal; Hydroload; O-ring; Mechanical Seal, Shaft Sealing, Elastomeric Seal.

employed to solve this engineering problem. As no sealing solution is perfect, one must weigh the positives and negatives of the seal selected. Particularly if the negatives cannot be managed effectively, it must seek other solutions… See more on steinseal…

- ABB Turbocharger TCR20 Diesel Engine Parts ATU

- Marine Engine Connecting Rods vs. Standard Connecting Rods

- SULZER chemical process pump seal SCZ32-160 SCZ50-250 SCZ80-200

- Proper Design of Cylinder Liners in Marine Diesel Engines

- Marine Propeller Shaft

- Sulzer RND76, RND76M, RD90, RND68M for Cylinder liner