Fuel Oil System for Marine Diesel Engine

What is fuel oil system in ship?

The fuel oil is delivered to the fuel injection pump through the fuel supply line, and the booster pump ensures that the fuel injection pump is always supplied with sufficient fuel. The amount of fuel delivered by the booster pump is much larger than the actual fuel required by the engine; the excess fuel is returned to the system mixing unit through the booster return pipe, and the booster pump draws fuel from it.

The specified boost pressure is regulated by a pressure holding valve located in the fuel return line of the engine. The main engine is designed to run on heavy oil during maneuvers. All lines to the fuel distributor on the cylinder head are heat traced and insulated.

The fuel distributor and injection valves are kept hot by the circulation of heated fuel from the booster pump. Each distributor is equipped with a priming valve to allow the system to prime with fuel after an injector has been replaced. For safety, all high-pressure pipes are wrapped with metal hoses. Any leaks are contained and directed to the alarm tank.

Where does fuel oil come from?

Fuel oil is obtained from petroleum distillation, either as a distillate or as a residue.

Relatively low-boiling small molecules in propane, naphtha, fuel oil and jet fuel (kerosene) are removed at the beginning of the fractionation process. Heavier products such as diesel and lubricants are less volatile and have slower distillation rates. Bunker fuel is the bottom of the barrel, and the only products denser than it is the carbon black feedstock and asphalt slag (bitumen) used to pave roads and seal roofs.

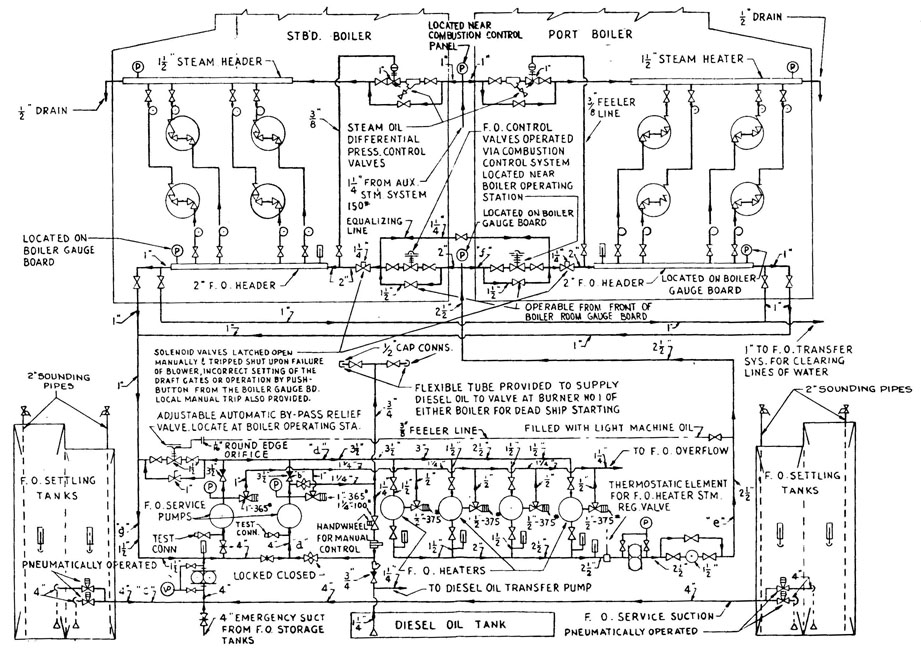

fuel delivery system

The system receives and stores fuel and delivers it to a sedimentation tank. Fuel is loaded through a deck fill connection, which provides a sample connection for sampling the fuel as it is brought on board. The HFO is loaded in a tank equipped with a heating coil.

When ready for use, the HFO is delivered to the fuel settling tank via an FO transfer pump equipped with a suction filter. The piping is arranged so that the pump can transfer the fuel between the tanks and then to the deck connection for unloading. Settling tanks are used to allow total water and solids to settle at the bottom.

Fuel Oil Service Pump

Two motor-driven service pumps feed the fuel service system. These pumps are vertical, rotary, 2-speed units with 20/40 GPM capacity and 350 psia discharge pressure. The pump discharge port has a pressure relief valve set to 365 PSIG to relieve pressure to the fuel settling tank. Pump speed selection is controlled from the fire compartment dashboard.

Fuel Oil service system operation

Before starting the fuel service system, the fuel settling tank should be filled and heated, if necessary, to the proper temperature for pumping. The suction valves on both inner or both outer settlers should be opened. The bypass valve around the fuel gauge should be open to prevent recirculated oil from registering on the gauge. The service pump and fuel heater should be aligned, but do not put steam on the heater until the pump starts. After the forced fan is activated, the solenoid valve can be locked open. Open the circulation valve slightly and start the pump. The oil is recirculated through the heater until the proper atomization temperature is reached. Care must be taken to avoid overheating the oil as this can cause the fuel to evaporate, causing the fuel pump to lose suction. This is especially important when recirculating the second boiler, as the loss of fuel suction affects the steam boiler.