Construction Explanation: What is a Marine Engine Bedplate?

The Marine Engine Bedplate is the base plate and lowest part of a marine engine, it supports the engine structure and is one of the most heavily loaded structural components of the engine. For large engines, the bedplate is made of flat-bottomed structural components. is the base plate and lowest part of a marine engine, it supports the engine structure and is one of the most heavily loaded structural components of the engine. For large engines, the bedplate is made of flat-bottomed structural components with a high surface finish.

What is a Marine Engine Bedplate made of?

Engine manufacturers, especially the large engines, rely primarily on a cast or prefabricated steel to make engine chassis. They always carefully choose the materials to use. More commonly, the material they inspect and test is mild steel with a maximum carbon content of about 0.23%.

For small engines, their bedplates are made of cast iron with vibration-reducing properties to avoid cracks during further engine use.

Bed boards made of cast iron or mixed with prefabricated steel are very durable. It can absorb heavy impact and deformation without breaking. In addition, they are flexible and can withstand longitudinal stress without tearing.

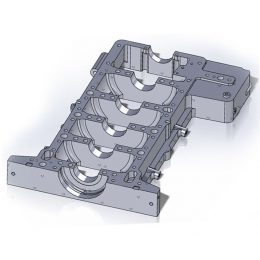

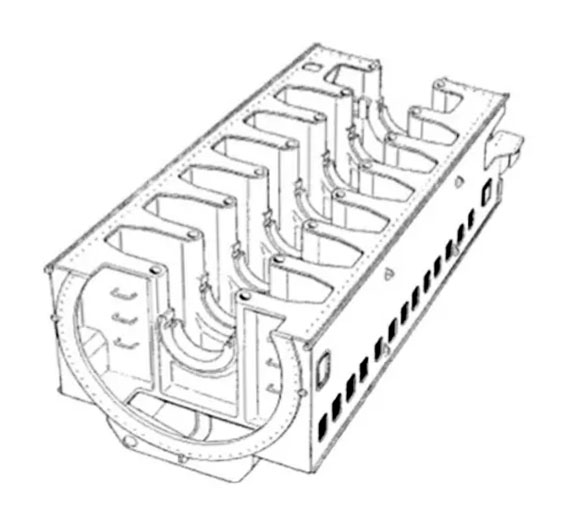

The Structures of marine engine bedplates

In most cases, the Marine Engine Bedplate comprises two longitudinal beams the same length as the engine it supports. Between these two longitudinal beams, there are beams connecting them. These beams are used to locate the main bearings and run the crankshaft in perfect alignment.

The structure of the base plate must be strong enough to support the weight of the rest of the engine. Also, if not cast well, the bottom plate may snap or crack when the ship bends because of buckling or sagging.

Incorrect soldering

Repairs to the platen include welding. Check to see if the weld is too deep or too shallow and could cause further problems during sailing.

Common Problems of Marine Engine Bottom Plates

The bottom plate may encounter some problems when it is transported to the shipyard and installed on the ship. That’s why routine inspections are necessary to raise issues and find solutions immediately.

corrosion

Corrosion can occur on the bottom plate as it is mainly in contact with water and oil as it is on the tank top. Frequent inspections are necessary to avoid serious damage to the engine.

crack

If the boat is stationary, keep checking for any cracks around the bottom plate or in the crankcase. Always pay attention to the bearing grooves, longitudinal beams, and the bases of the beams and main bearings that connect them.

Loose bolts and nuts

Check the bolts and nuts on the base plate frequently. Get in the habit of marking to see if a nut or bolt is moving slowly over time. Check if the bolts and nuts are from the frame or from bolts and nuts fastened to the hull structure.

Our Marine Engine Spare parts:

Construction of Marine Engine Bedplate:

The bedplate acts as the primary strength member, maintaining proper alignment and supporting the weight of the assembly. It must be able to withstand and transmit the wave forces generated during operation to the ship structure. In addition, it can collect lubricating oil.

The low-speed engine design includes the seepage tank section, reinforced in the form of members and webs.

A beam is installed between each stroke of the crankshaft. These support the main bearing saddle and tie rod connections. They are attached to the structure by extensive butt welds. In order to lower the height of the engine, the sump of the bottom plate may be sunk, allowing it to fit into a groove in the ship’s structure.

Double butt welds require plate and weld preparation if possible. Parts require regular internal inspection, especially for fatigue cracks in beams. The tie bolts should be checked for tightness. welds, if possible. Parts need to be regularly inspected internally, especially beams for fatigue cracks. The tie bolts should be checked for tightness.

The important functions of the Marine Engine Bedplate:

- Supports static loads of fixed engine frame and block

- Supporting the dynamic load of the running gear

- Supports the crankshaft and keeps it perfectly aligned

- Distribute static and dynamic loads from engine operation to the ship’s structure

- Collects crankcase oil and transfers it to the sump tank from where the oil pump can suck it in

- Secure the engine to the top of the tank to transfer the propeller thrust to the hull structure

- Contributes to improving the hull strength of the engine room bottom structure

The Bed plate is held together with the A-frame and engine mounts by tie rods. Check that the tie rods are tight and that there are no loose parts between the frame and the base plate.

Failure of fixing bolts: The fixing bolts hold the bottom plate in place with the bottom structure. Check whether the fixing bolts are loose, and if found loose, tighten them according to the manual. Also, check for shear and wear on the compression bolts… See more on marine Engineering 360