Marine Fuel Management System

Introduction

A fuel management system was not initially used on ships; however, as the cost of marine fuel has increased, it has become an essential piece of equipment on board. The main objective of the system is to reduce the fuel usage of the vessel by increasing the operating efficiency of the fuel system.

The fuel system of a marine diesel engine can be divided into two parts – the fuel supply and the fuel injection system. Fueling involves supplying fuel oil suitable for use by the injection system. Marine fuel oil systems include various piping systems provided for the filling, storage, transfer, unloading, and handling of fuel oil.

Fuel Oil Transfer System

This system receives stores, and delivers fuel to settling tanks. Fuel oils are loaded through deck fill ( bunker manifold ) connections with sample connections to allow the fuel to be sampled as it is brought aboard. HFO is stored in tanks equipped with heating coils.

In preparation for use, HFO is transferred to the fuel oil settling tanks via FO transfer pumps which are equipped with a suction strainer. Piping is so arranged that the pumps can transfer fuel between storage tanks and then to the deck connections for offloading. Settling tanks are used to permit gross water and solids to settle on the bottom.

Fuel Oil Treatment System

The system receives storage and delivers fuel to a settling tank. Fuel is loaded through a deck fill (fuel manifold) connection with a sample connection to sample the fuel as it is brought on board. HFO is stored in tanks equipped with heating coils.

When ready for use, the HFO is delivered to the fuel settling tank via an FO transfer pump equipped with a suction filter. The piping is arranged so that the pump can transfer the fuel between the tanks and then to the deck connection for unloading. Settling tanks are used to allow total water and solids to settle at the bottom.

Fuel tank overflow system

All tanks overflow to overflow tanks through lines with sight glass. The line also includes a flow alarm. There is a level alarm in the overflow tank that will activate when the tank is one-quarter full.

All tank vents are installed so that oil cannot spill onto decks or machinery spaces to avoid fires. The overflow tank has an exhaust opening to the deck and is fitted with a wire mesh diaphragm.

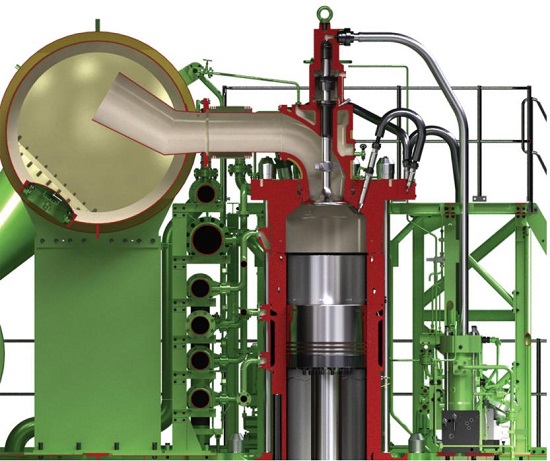

Fuel oil supply for a two-stroke diesel engine

Low-speed two-stroke diesel engines are typically configured for continuous operation on heavy fuel and have a diesel supply available for motoring purposes.

The oil in the system shown is stored in a double bottom tank from which it is pumped into a settling tank and heated. After passing through the centrifuge, the clean, heated oil is pumped to the daily service tank.

To ensure a continuous supply of fuel to the mixing tank via the fuel line and flow meter, the heavy fuel tank should be positioned high enough above the mixing tank. To exclude the possibility of heavy fuel oil entering the diesel daily fuel tank, the latter should be located above the heavy fuel fuel tank or protected by a check valve.

Oil flows from the daily service tank to the mixing tank through a three-way valve. A flow meter is installed in the system to monitor fuel consumption. The booster pump is used to deliver the oil to the engine driven fuel pump after passing through the heater and viscosity regulator. The fuel pump delivers high-pressure fuel to the injectors.

Viscosity regulators adjust the temperature of the fuel to provide the proper viscosity for combustion. A pressure regulating valve ensures a constant pressure supply to the engine-driven pump, and a preheat bypass is used to heat the fuel before starting the engine.

It is possible to install a diesel daily fuel tank connected to the system via a three-way valve. The engine can be started and operated using diesel or a combination of diesel and heavy fuel oil. The mixing tank collects the recirculated oil and also serves as a buffer or reserve tank to supply fuel when the daily service tank is empty.

If there is a problem with a heavy oil engine during handling, whether the engine is operated via bridge or cabin controls, there should be no hesitation in switching to diesel.

Engines designed to run on heavy fuel oil must be used in accordance with the manufacturer’s instructions. All other types of mainframes must be run on diesel fuel according to the manufacturer’s instructions.

Various safety devices in a fuel system for a diesel engine:

Quick shut-off valve on settling/serving tank

Safety valves on 2 pumps/heaters

Quick Shutoff Valve on Mix/Vent Tank

Pipe lag/saved under pump and heater

Low fuel pressure alarm

High fuel pressure alarm

Low fuel temperature alarm

High fuel temperature alarm

Emergency remote stop of the pump

The high-pressure pipe between the fuel injection pump and the injector is double-layered.