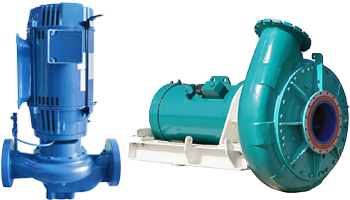

Marine Dredge Pump

Marine Dredge Pump

The dredge pump is a horizontal centrifugal pump, which is the heartbeat of the dredger. It is designed to handle suspended particulate materials and solids of limited size. A cutter suction dredger could not transport mud without a dredger pump.

Dredge Pumps are one of the most robust equipment for moving material. Dredging utilizes these high-powered pumps to transfer solids and liquids through a pipeline over a set distance and often involves working in sensitive or harsh conditions.

The dredge pumps are abrasive-resistant, making them ideal for grinding through rocks, sludge, sand, slurry, and many other objects. As a top dredge manufacturer, DAE Pumps provides a variety of options in dredging.

working principle

The dredge pump is a centrifugal pump, which is mainly composed of a pump casing and an impeller. The impeller is mounted in the pump casing and connected to the drive motor by a shaft. The front side of the pump casing is closed with a suction cover to which the suction pipe is connected. The discharge port of the dredging pump is mostly located on the upper side of the pump and is connected to the discharge pipe.

An impeller can be likened to a fan that displaces air, and by doing so, it creates centrifugal force. At the inlet/suction pipe, negative pressure or vacuum picks up the slurry. At the discharge end of the pump, the overpressure transports the slurry along the discharge line.

Common Dredging Applications

- Beach Restoration

- Coastal Protection

- Ecosystem Restoration

- Fly Ash Dredging

- Lake Dredging

- Land Reclamation

- Marina Dredging

- Mining Dredge

- Navigation Dredging

- Port and Harbor Dredging

- Reservoir Dredging

- River Dredging

- Sand & Gravel Dredging

- Mine Tailings Dredging

Dredging Pumps in Ships

Small dredgers usually have only one dredging pump, while larger vessels can accommodate multiple pumps. For example, the TSHD can have one or two pumps in the pump room and/or a submersible dredging pump in the suction line.

When the TSHD is equipped with an underwater pump, the submersible pump usually does the loading of the hopper without the aid of a pump in the pump chamber. The pump room contained is mainly used for the ship to be brought ashore by siphoning or pampering bowingddition to those on board. The CSD can also be equipped with submersible dredging pumps to increase production and increase suction capacity. Booster stations containing additional dredging pumps can also be added to the system when mud must be transported over long distances through pipelines.

Our Dredge Pump Benefits

- Provides environmentally superior dredging methods to meet stringent water quality standards.

- The high mud density minimizes the volume of sediment upland sediment to be treated and disposed of.

- The sediment at the tip showed little cloudiness or resuspension.

- High productivity can be achieved. Comparable to larger conventional suction dredgers.

- Able to pass large amounts of wood chips and other foreign matter in the sediment without clogging.

- After resolving initial start-up issues, the prototype dredger proved to be able to operate continuously and reliably.

- Discharging sediment into the water column results in low turbidity and TSS levels, well within the limits of stringent water quality standards, without the need for sediment containment curtains.

- The technology is capable of pumping dense slurries over long distances, providing an alternative to pipelines that transport sediment to distant disposal sites.

Keywords: diesel dredge pump, dredge pump design, gravel dredge pump, Slurry Pump

- How Marine Engine Connecting Rods Affect Your Engine Performance

- Proper Design of Cylinder Liners in Marine Diesel Engines

- Marine Engine Connecting Rods: The Ultimate Guide

- Revving Up with Ship Engine Crankshaft Parts!

- Marine Diesel Engine Turbocharger

- Expert Tips for Choosing the Right Marine Propeller Shaft for Your SHIP