Marine Check Valves

Marine Check Valves

Marine check Valves, also named as Non-Return Valves (NRV) or One-Way Valves, is a device that only allows the flow of fluids in one direction. Check valve open with forward flow and close against reverse flow. The medium flows in from the inlet end (the lower side) and flows out from the outlet end (the upper side). Valve is opened when inlet pressure is greater than the sum of disc weight and flow resistance. Conversely, the valve is closed when the medium flows back.

Check valves differ considerably from other members of the valve family and the prime function of a check valve is to protect mechanical equipment in a piping system by preventing reversal of flow by the fluid.

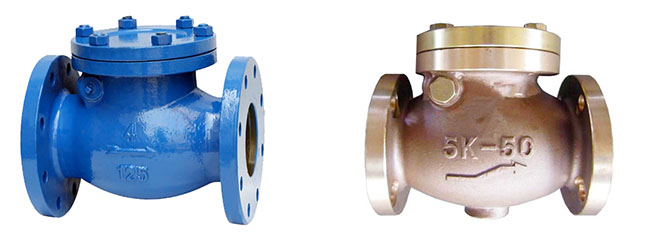

Check Valve Product Range

- Design: JIS, DIN, API, GB

- End Connection: BW, RF, RTJ, UNION

- Size: 1-1/2”~48”, DN40~DN1200, 40A~1200A

- Pressure: JIS 1K~63K, 125LB~2500LB, PN10~PN420

- Material: Cast Iron, Stainless Steel, Bronze

3 Types of Marine Check Valves

- Swing Check Valve

- Piston or Lift Check Valve

- Wafer Check Valve

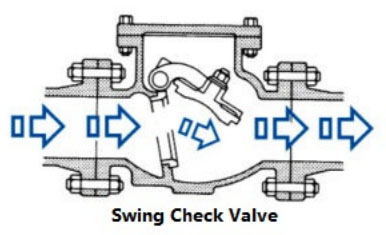

Swing Check Valve

The Swing Check Valve is the most popular of all check valves, offering very little resistance to the flow when it is wide open. The closing element (disc) swings open and shut like a trap door about a hinge outside the seat. A replaceable composition washer may be fitted on the disc and takes most of the wear. A loose pin hinge ensures the disc closes when the flow diminishes to zero.

Swing check valves should be mounted in the horizontal position, but may also be mounted in the vertical position, provided the disc is prevented from reaching the stalling position. Swing check valves are companions to gate valves and are commonly used on all lines where fluid-friction loss is of prime importance. They are recommended for applications where the reversal of flow is not so frequent, to prevent “valve chattering”. Dirt and viscous fluids cannot easily hinder the rotation of the disc around the hinge.

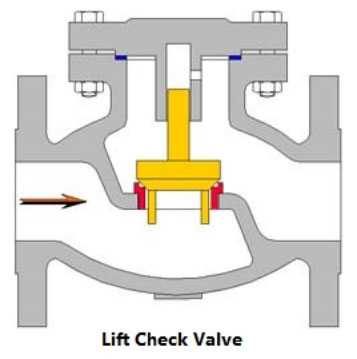

Lift or Piston Check Valve

Lift Check Valve (also known as Piston Check Valve) has a guided plug which is lifted by the higher pressure of the inlet or upstream fluid to allow flow to the outlet or downstream side. When the inlet pressure is no longer higher, gravity or higher downstream pressure will cause the disc to lower onto its seat, shutting the valve to stop reverse flow. Lift check valves have an advantage over most other types of check valves in that they need only a relatively short lift to obtain full valve opening.

In the majority of lift check valves, the closure member moves in a guide to ensure that the seating’s mate on closing. However, such guiding also has a disadvantage in that dirt entering the guide can hang up the closure member, and viscous liquids will cause lazy valve operation or even cause the closure member to hang up. These types of lift check valves are therefore suitable for low viscosity fluids only, which are essentially free of solids. This type of check valve does not have the tendency to slam as does the Swing Check Valve and is preferred for installations having irregular or frequent reversals of flow.

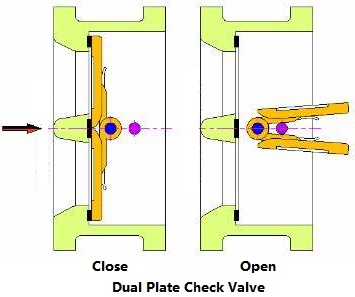

Wafer Check Valve

Wafer type check valves are used to prevent fluid from reversing in a piping system. These valves are named “wafers” because of their thin and compact size, unlike other check valves. Wafer type check valves are automatic and thus they do not need a valve actuator or valve operator. Wafer type check valve manufacturers design these valves with a high level of reliability because they are used in critical applications such as in freshwater supply, where any small level of dirty fluid going back to the freshwater may cause health problems. Wafer type check valves are used in different applications, such as low to high temperature and pressure applications. As such, the type of materials used to construct internal parts of the valve determines the level of temperature where the valve can be used.

Our Product Range

- Design: JIS, DIN, API, GB

- End Connection: BW, RF, RTJ, UNION

- Size: 1-1/2”~48”, DN40~DN1200, 40A~1200A

- Pressure: JIS 1K~63K, 125LB~2500LB, PN10~PN420

- Material: Cast Iron, Stainless Steel, Bronze

- S70MCC Big Water Jacket Shipped

- Marine Cylinder Liner Measurements: Standards & Insights.

- Replacing a Diesel Engine Cylinder Liner: Important Considerations

- The Importance of Marine Engine Connecting Rods in Performance Engines

- MAN B&W S70MC S70MC-C8 L70MC Spares for Diesel Engines

- Ship spare parts S60MC S50MC S80MC K80MC K90MC Cylinder liner