Diesel Engine Cylinder liner

Diesel engine cylinder liner:

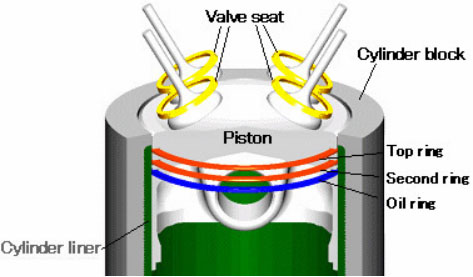

A cylinder liner is a cylindrical part to be fitted into an engine block to form a cylinder. It is one of the most important functional parts to make up the interior of an engine.

This is called Diesel engine cylinder liner but some countries (or companies) call this Cylinder sleeve. These are the main functions of Cylinder Liners.

Heat transfer

The cylinder liner acts as inner wall of the cylinder and forms a sliding surface for the piston rings while retaining the lubricant within. The most important function of cylinder liners is the excellent characteristics of sliding surfaces. That is why you should always prefer a high-quality standard liner with a certificate.

Four important points that are applicable to cylinder liners are 1. High anti-galling properties 2. Less wear on the cylinder liner itself 3. Less wear on the partner piston ring 4. Less consumption of lubricant.

Material for Cylinder Liner:

For cylinder liners, Inconel has been commonly used. Nichrome irons used include:

Carbon 3.5%;

Manganese 0.6%;

Phosphorus 1.5%;

Sulfur 0.05%;

Silicone 2%;

Nickel 2%; and

Chromium 0.7%.

To improve wear resistance, the liner is hardened by heating to 855°C-865°C for 30 to 40 minutes and then quenched in oil. This type of heat treatment increases the life of the bushing by a factor of three compared to grey cast iron or cast iron cylinders.

Why inquire NOAH…

Cylinder liners take care your engine works well and keeps running when replaced in time. In combination with the right piston rings, the right lubricant, and the service is executed on time a cylinder liner has maximum lifetime.

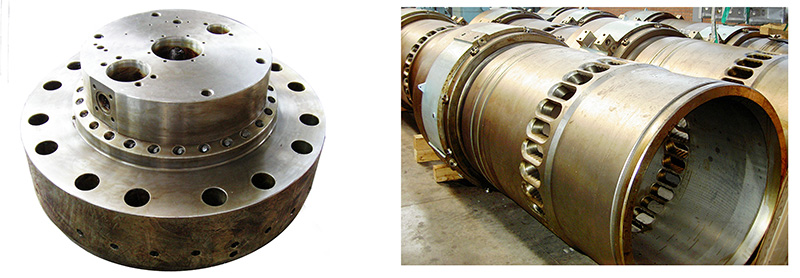

Not only we have the knowledge of in-house produced cylinder liners, but we are also known with specific executions and know if a modified cylinder liner is needed based on the by you provided drawings and markings.

Transporting a cylinder liner

As cylinder liners can be large items it is good to check on forehand the options to supply in time and from what port. With NOAH… you have several options for taking large items on board for example in the Europe region or the Asia region. The in-house “Maritime Logistics” department can take care of the shipment.

Replacing a cylinder liner

When an overhaul is planned for replacing a cylinder liner or when the engine is damaged in a way that the liner needs to be replaced it’s important to have all relevant data available such as drawings, codebook pages, and technical files. It can of course be possible an anti-polishing ring is needed or other parts need replacement as well during the overhaul of the cylinder liner. Have a look at our product catalog for all wear and tear parts for your marine diesel engine. For advice about price, lead times, stock, executions, drawings or help you can always contact our specialist from the sales department.

What Is Cylinder Liner? From MechanicalJungle: