Crankshaft Damage in Diesel Engines: Detection and Repair

Crankshaft Damage in Diesel Engines

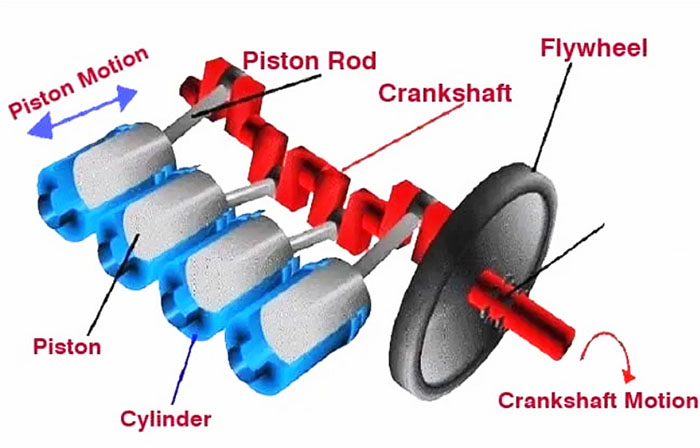

The crankshaft is the most vital part of any engine, including diesel engines. It converts the linear motion of the piston into rotational motion, producing power to drive the vehicle. However, due to the high stress and pressure that the crankshaft endures, it can become damaged. Crankshaft damage can lead to severe consequences, including engine failure. Therefore, it is essential to identify the causes, symptoms, and repair options for crankshaft damage in diesel engines.

Causes of Crankshaft Damage in Diesel Engines

Several factors can cause crankshaft damage in diesel engines. The most common cause is excessive vibration caused by an unbalanced or misaligned engine. This can lead to fatigue, cracks, or even complete failure of the crankshaft. Another cause of crankshaft damage is oil starvation due to inadequate lubrication. This can lead to severe overheating and warping of the crankshaft. Additionally, improper installation or assembly can cause damage, leading to premature wear or even failure.

Symptoms of Crankshaft Damage in Diesel Engines

Recognizing the symptoms of crankshaft damage is crucial to prevent further damage and costly repairs. The most common symptoms include engine knocking or rattling noises, vibration, loss of power or acceleration, and excessive smoke emissions. In severe cases, the engine may become completely inoperable. If any of these symptoms are present, it is essential to take action immediately to prevent further damage.

Diagnosis of Crankshaft Damage in Diesel Engines

Diagnosing crankshaft damage in diesel engines requires a thorough inspection of the engine. This includes a visual inspection of the crankshaft for signs of wear, cracks, or other damage. Additionally, specialized equipment can be used to measure the crankshaft’s roundness, straightness, and bearing clearances. These diagnostic tests can determine the extent of the damage and help identify the best course of action for repairs.

Repair Options for Crankshaft Damage in Diesel Engines

The repair options for crankshaft damage in diesel engines depend on the extent of the damage. Minor damage, such as surface wear or minor cracks, can often be repaired through regrinding or polishing. However, more severe damage may require the replacement of the crankshaft entirely. In some cases, a used or refurbished crankshaft may be an option. It is essential to consult with a professional mechanic to determine the best course of action for your specific situation.

Prevention of Crankshaft Damage in Diesel Engines

Preventing crankshaft damage in diesel engines is essential to avoid costly repairs and downtime. Regular maintenance, including oil changes and inspections, can help prevent oil starvation and ensure proper lubrication. Additionally, proper engine alignment and balancing can help reduce excessive vibrations that can cause fatigue and damage to the crankshaft. Finally, it’s essential to follow the manufacturer’s recommended installation and assembly procedures to ensure proper fit and function.

Crankshaft Damage in Diesel Engines

In conclusion, the crankshaft is a vital component of any diesel engine. Recognizing the causes, symptoms, and repair options for crankshaft damage is essential to keep your engine running smoothly and avoid costly repairs. Regular maintenance and preventative measures can help prevent damage and prolong the life of your engine. It is crucial to consult with a professional mechanic to diagnose and repair any issues with your crankshaft to ensure the safe and reliable operation of your diesel engine.

- Comparison of Marine Cylinder Liner Coatings

- ABB Turbocharger TCR20 Diesel Engine Parts ATU

- SULZER mechanical seal SCZ32-160 SCZ50-250 SCZ80-200

- Sulzer RND76, RND76M, RD90, RND68M for Cylinder liner

- “The Importance of Cylinder Liners in Marine Diesel Engines: Functions, Types, and Maintenance”

- Marine Propeller Shaft Maintenance: Key Considerations for Performance